Table of Contents

The different seam types is essential for anyone interested in sewing, whether you’re a beginner or an experienced maker. This guide explains the most common seam types, how to sew them, their best uses, and practical tips for success.

The German word “Nahttypen” translates to “seam types” in English, and these seams are crucial for the structural integrity, aesthetic appeal, and functional performance of any sewn product.

Comprehending the different types of seams is essential for designers, tailors, seamstresses, and hobbyists alike.

This guide provides an in-depth exploration of Nahttypen—what they are, the various kinds, their applications, and how innovations in materials and techniques are shaping their evolution.

Whether you’re a beginner eager to learn about sewing or a professional seeking to refine your craft, this guide offers essential insights to enhance your knowledge and skills.

What Are Nahttypen?

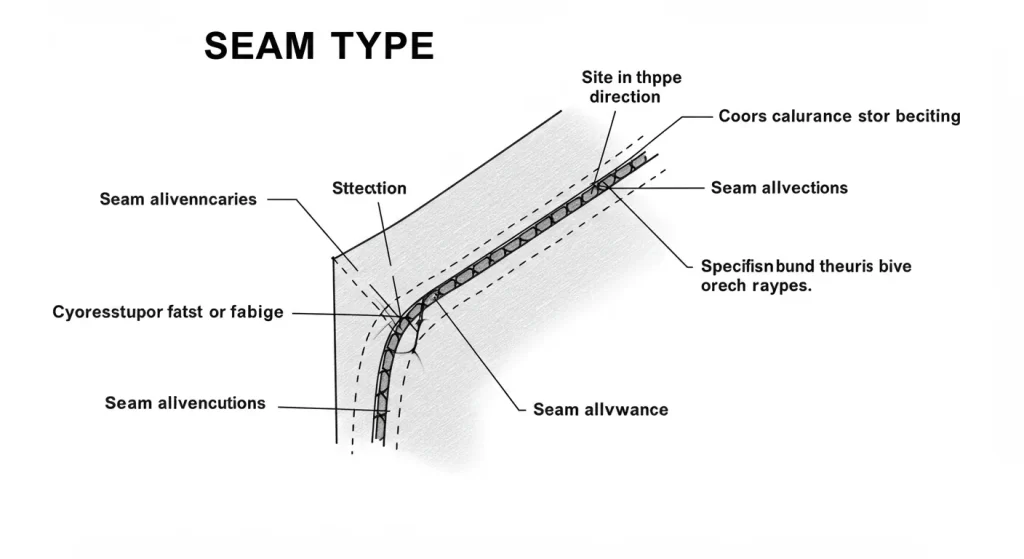

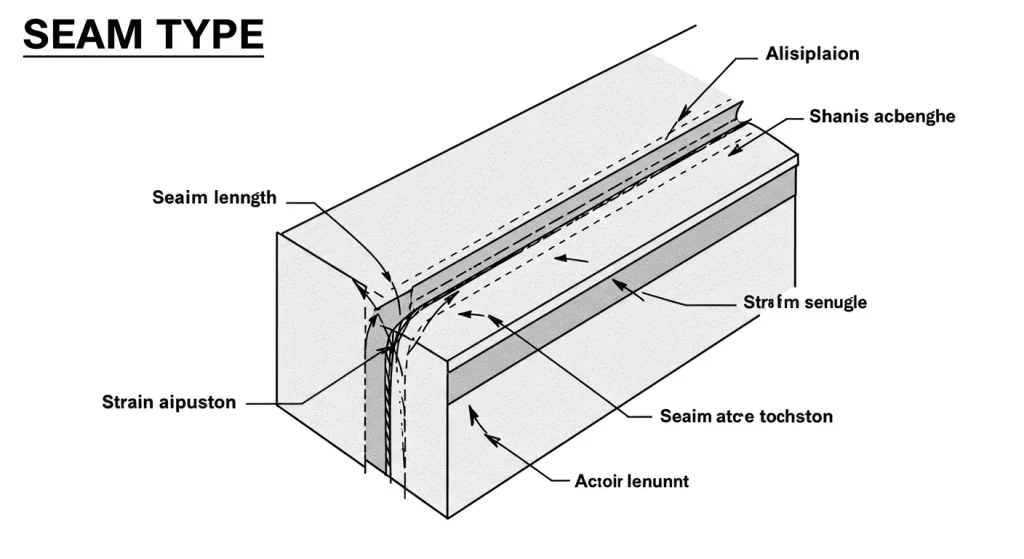

At its core, a Naht or seam is where two or more pieces of fabric are joined together by stitching. However, not all seams are created equal. The term Nahttypen categorizes these seams based on their construction method, purpose, strength, and finish. Each seam type has distinct characteristics that make it ideal for specific fabrics and uses.

Seams serve multiple purposes in the textile world:

- Structural strength: Holding fabric pieces together under tension or stress.

- Design aesthetics: Influencing the look and feel of a garment or product.

- Functionality: Allowing flexibility, stretch, waterproofing, or insulation.

Choosing the right Nahttyp is critical for durability, comfort, and style.

1. Plain Seam (Einfache Naht)

What is it?

The plain seam is the most basic and widely used seam in garment construction.

How to sew:

- Place fabric pieces right sides together.

- Sew a straight stitch along the seam line.

- Finish raw edges with a zigzag or serger.

Best for: Woven fabrics (cotton, linen)

Difficulty: Beginner

Strength: Medium

Common mistakes: Not finishing edges, leading to fraying.

2. French Seam (Französische Naht)

What is it?

A French seam hides raw edges inside, creating a neat finish—ideal for delicate or sheer fabrics.

How to sew:

- Place fabric wrong sides together, sew a narrow seam.

- Trim seam allowance, press.

- Fold right sides together, sew another seam to enclose edges.

Best for: Lightweight, sheer fabrics (silk, chiffon)

Difficulty: Intermediate

Strength: Medium

Common mistakes: Seam too wide, visible raw edges.

3. Flat-Felled Seam (Kappnaht)

What is it?

A strong, durable seam often used in jeans and sportswear. Both raw edges are enclosed for a flat finish.

How to sew:

- Sew fabric right sides together.

- Trim one seam allowance.

- Fold the other allowance over, tuck in trimmed edge, and stitch down.

Best for: Heavy fabrics (denim, canvas)

Difficulty: Intermediate

Strength: High

Common mistakes: Bulky seams if not trimmed properly.

4. Overlocked/Serger Seam (Overlocknaht)

What is it?

A seam and edge finish in one, created with an overlocker/serger machine.

How to sew:

- Align fabric edges.

- Run through serger to sew and finish edges at the same time.

Best for: Stretch fabrics, knits

Difficulty: Beginner (with serger)

Strength: Medium

Common mistakes: Incorrect tension, uneven edges.

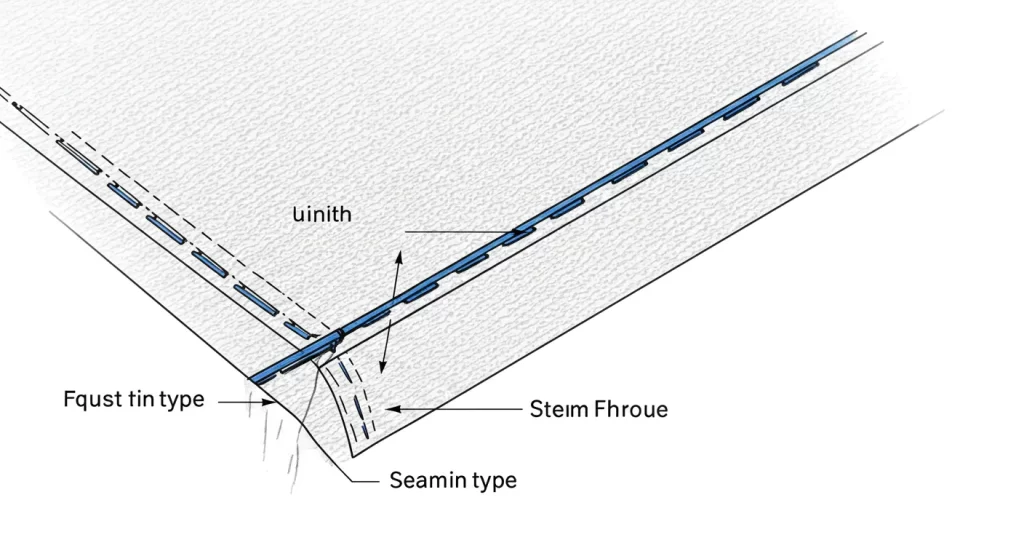

5. Lapped Seam (Überlappte Naht)

What is it?

A seam where one fabric edge overlaps another, then stitched down—common in leather or non-fraying materials.

How to sew:

- Overlap fabric edges by desired amount.

- Stitch close to both raw edges.

Best for: Leather, felt, vinyl

Difficulty: Beginner

Strength: Medium

Common mistakes: Uneven overlap.

Historical Context and Evolution of Nahttypen

Seams have been used in textiles for thousands of years. From the earliest hand-stitched garments made with bone needles and sinew to modern, highly specialized seams in technical textiles, the development of Nahttypen has mirrored advancements in technology and materials.

Over time, the rise of industrial sewing machines, synthetic threads, and fabric innovations has refined traditional seam types. Today, we see performance-driven seams in sportswear, outdoor gear, and medical fabrics. Similarly, haute couture fashion often utilizes intricate seam constructions to create unique silhouettes and dramatic effects.

Classification of Nahttypen: The Basics

Nahttypen can be broadly divided into several categories based on their construction. Below are the most commonly used types, along with their applications:

1. Plain Seam (Einfache Naht)

The plain seam is the simplest and most common type, where two fabric edges are placed together and stitched with a straight stitch. After stitching, the raw edges are typically finished to prevent fraying using methods such as serging or pinking shears.

Also Read: USA Poples, Copules Safely Dating On Platform: love2love.lv

- Applications: Most everyday garments, home textiles.

- Pros: Easy and fast to sew; works on a wide range of fabrics.

- Cons: Raw edges may fray if not finished; they are not as durable under heavy stress.

2. Flat-Felled Seam (Flachnaht)

The flat-felled seam is renowned for its strength and clean finish. It involves folding and sewing the fabric edges flat against each other, enclosing the raw edges inside the seam. This type of seam is famously used in denim jeans.

- Applications: Jeans, workwear, upholstery, and sportswear.

- Pros: Extremely durable and neat; raw edges are fully enclosed.

- Cons: More time-consuming to sew; adds bulk to the seam area.

3. French Seam (Französische Naht)

French seams are neat, enclosed seams that enclose raw edges inside two stitching lines. They are ideal for delicate fabrics, such as lace, chiffon, or silk, where raw edges can detract from the aesthetic quality.

- Applications: Lingerie, fine blouses, wedding dresses.

- Pros: Elegant, clean finish; protects fabric edges.

- Cons: Not suitable for bulky fabrics; requires precision.

4. Bound Seam (Besetzte Naht)

The bound seam uses a binding tape or fabric strip to cover the raw edges. This is often used in high-end garments or technical fabrics that require extra protection.

- Applications: Activewear, rainwear, designer clothing.

- Pros: Enhances durability; adds aesthetic value.

- Cons: Requires additional materials and sewing skills.

5. Lapped Seam (Überlappnaht)

A lapped seam involves overlapping one fabric edge onto another and stitching them down. This seam is commonly used in leatherwork and heavy fabrics where durability is paramount.

- Applications: Leather jackets, outdoor gear.

- Pros: Strong and resistant to stress.

- Cons: Visible seam; may be bulky.

6. Flat Seam (Flachnaht)

Flat seams are created by butting the fabric edges together and sewing them flat without overlapping. This type of seam is commonly found in sportswear to reduce bulk and increase comfort.

- Applications: Sportswear, activewear.

- Pros: Minimizes chafing; lightweight.

- Cons: Less durable than overlapped seams.

7. Decorative or Embellished Seams

Decorative seams are primarily designed for visual impact and include techniques like topstitching, embroidery, or appliqué. These seams add a unique flair to garments and home textiles.

Also Read: Wepbound: The Digital Framework That Could Reshape the Web by 2026

- Applications: Fashion garments, home decor.

- Pros: Adds a unique style and visual interest.

- Cons: May sacrifice some strength for aesthetic purposes.

Technical Aspects and Sewing Considerations

Understanding Nahttypen also requires considering several technical factors that influence seam quality:

- Fabric Compatibility: Stretch fabrics need seams that allow elasticity, while woven fabrics require stable seams.

- Thread Selection: Polyester threads are strong and elastic, while cotton threads offer softness.

- Seam Allowance: The width of the fabric between the stitch and edge affects durability and flexibility.

- Seam Finishing: Techniques like serging or binding are crucial for extending the life of seams.

Innovations in Seam Technology

Modern technologies have expanded the range of Nahttypen and opened up new possibilities in seam construction. Some notable innovations include:

- Seam Taping: Heat-bonded tape is applied over seams to make garments waterproof.

- Flatlock Stitching: This method is used in activewear for a stretchable, comfortable fit.

- Ultrasonic Welding: Joins synthetic fabrics without sewing.

- Bonded Seams: Adhesive layers replace stitching, creating smooth, waterproof finishes.

These advancements are particularly evident in sportswear, medical textiles, and outdoor gear.

How to Choose the Right Nahttyp?

Selecting the appropriate seam type depends on several factors:

- Fabric type: Lightweight, heavy, stretch, or delicate.

- End-use: Fashion, industrial, outdoor, or upholstery.

- Desired aesthetics: Invisible, decorative, or rugged.

- Durability needs: Daily wear, heavy use, or occasional wear.

- Manufacturing capabilities: Equipment and skills available.

For example, a waterproof jacket requires taped seams, while a wedding dress benefits from French seams.

Common Mistakes and How to Avoid Them

When working with Nahttypen, some common mistakes can weaken your seams or affect the overall finish:

- Incorrect seam allowance: This can lead to weak seams or puckering.

- Ignoring fabric grain: Cutting against the grain can distort seams.

- Wrong thread tension: This can cause skipped stitches or puckering.

- Poor seam finishing: This leads to fraying and reduced durability.

Attention to detail and testing sample seams can help avoid these common issues.

Seam Types Comparison Table

| Seam Type | Strength | Best For | Fabric Type | Difficulty |

|---|---|---|---|---|

| Plain | Medium | Everyday clothes | Woven | Beginner |

| French | Medium | Lingerie, blouses | Lightweight, sheer | Intermediate |

| Flat-felled | High | Jeans, workwear | Heavy | Intermediate |

| Overlocked | Medium | T-shirts, activewear | Stretch, knit | Beginner |

| Lapped | Medium | Leather, crafts | Non-fraying | Beginner |

Care and Maintenance of Seams

Proper care and maintenance are key to developing the life of your seams:

- Always follow the manufacturer’s washing instructions.

- Avoid harsh chemicals or high heat.

- Repair small seam damages early to prevent further issues.

- Reinforce stress points if necessary.

Closing Words

Nahttypen forms the silent yet crucial foundation of everything sewn—from high fashion to everyday clothing, from technical gear to upholstery. Each seam type has its benefits and drawbacks, influenced by fabric, use, and aesthetic desires.

Staying informed about both traditional and modern seam types empowers creators to produce garments that are not only beautiful but also functional and durable.

Whether you are threading a needle for the first time or designing the next generation of performance wear, a deep understanding of Nahttypen enhances your craftsmanship and elevates your final creations.

FAQs

Which seam is strongest?

Flat-felled seams are the strongest and most durable, ideal for heavy-duty garments.

Can I sew French seams on thick fabric?

French seams work best on lightweight fabrics. For thick materials, try a flat-felled or lapped seam.

How do I stop seams from fraying?

Finish raw edges with a zigzag stitch, overlock, or use seam binding.

Are flat-felled seams stronger than plain seams?

Yes, flat-felled seams are much stronger and more durable, as the raw edges are enclosed, and the fabric layers are folded flat.

Can seams stretch with stretch fabrics like jersey or spandex?

For stretch fabrics, seams like flatlock or seams sewn with stretch stitches are recommended to ensure comfort and durability in activewear.

About the Author

Written by [webinxs] more details:Email: info@wendywaldman.com

, a sewing enthusiast with over 10 years of experience in garment construction and textile design.